Torsion Spring Tester

The TST is a manually operated torque / angle tester that is available in seven force ranges: 0.3, 3, 25, 100, 200, 500 and 1,300 in-lb. The solid steel base and aluminum frame is rugged for durability in many different testing environments. The TST, like all LSI testers, comes standard with an NIST traceable certificate of calibration.

The TST is a manually operated torque / angle tester that is available in seven force ranges: 0.3, 3, 25, 100, 200, 500 and 1,300 in-lb. The solid steel base and aluminum frame is rugged for durability in many different testing environments. The TST, like all LSI testers, comes standard with an NIST traceable certificate of calibration.

.embed-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%; }

Absolute Zero

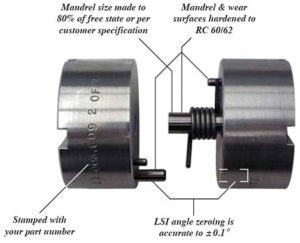

Take the guesswork out of testing with LSI’s revolutionary absolute zeroing technique. Used with custom interchangeable tooling, this technique improves repeatability of setups and results during testing. Parts are then measured against the nominal dimensions according to the drawing or specifications, not to a relative point requiring intuition and guesswork.

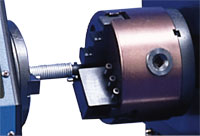

Custom Interchangeable Tooling

Using LSI’s custom interchangeable tooling technique, you can machine tooling blanks to fit your specific applications or send the information to us and we will do the work for you.

Using LSI’s custom interchangeable tooling technique, you can machine tooling blanks to fit your specific applications or send the information to us and we will do the work for you.

- Achieve 30 second tool-less changeovers from type to type

- Identical setups each time enhance repeatability

- Pre-machined blanks make tooling inexpensive and standardized

- Tooling can be designed to exactly match assembly features for best correlation

- Built-in angle zeroing provides ± 0.1° setup accuracy every time

- The best solution for repeating parts or specific spring types or families

Click here for more details

Universal Tooling

With the universal tooling supplied by LSI, you can test many parts with no special fittings. This is great for unique or one-time job runs with a minimum of setup time.

With the universal tooling supplied by LSI, you can test many parts with no special fittings. This is great for unique or one-time job runs with a minimum of setup time.

Universal Tooling Example

- 2″, 3″ & 4″ universal fittings

- A conventional approach that has good flexibility in making setups

- Includes chuck, mandrill set to 17/32″ diameter and reaction plate

View Universal Tooling Kit

Rapid Changeovers

Both custom and universal tooling is designed to be changed in seconds… YES! In just seconds, you can go from one setup to the next, maintaining your repeatability and reproducibility. Setups within ± 0.1°.

Smart Interchangeable Torque Cartridges

Switch from one torque cartridge to another in just minutes, allowing for a single tester to test a wide range of capacities quickly and accurately. Smart torque cartridges can be digitally calibrated. You can also send in only the smart torque cartridge to LSI for remote calibration (full system calibration is better than individual component calibration).

Switch from one torque cartridge to another in just minutes, allowing for a single tester to test a wide range of capacities quickly and accurately. Smart torque cartridges can be digitally calibrated. You can also send in only the smart torque cartridge to LSI for remote calibration (full system calibration is better than individual component calibration).

Delicate lower-capacity torque cartridges feature overload-preventing lockout mechanisms

Limit Lights & Full Statistical Analysis

Part sorting using bright LED limit lights for good / bad parts and a statistical summary printout that includes a histogram and data run chart.

This software option lets the user program the limit lights to make sorting reliable and efficient. This option also uses the programmed limits to enable the Mean, Standard Deviation, Range, Range Chart, Histogram, Cp and Cpk statistical printed outputs. Limit Lights and Full Statistics Analysis is a tester software feature. A PC is not needed for this software.

This software option lets the user program the limit lights to make sorting reliable and efficient. This option also uses the programmed limits to enable the Mean, Standard Deviation, Range, Range Chart, Histogram, Cp and Cpk statistical printed outputs. Limit Lights and Full Statistics Analysis is a tester software feature. A PC is not needed for this software.

Click here for print samples

Digital Control Panel

The TST has a built-in mean, standard deviation, range, statistical summary and data logger that can store up to 1,800 test points. It also has automatic deflection compensation, which corrects for torque windup and always displays accurate angle measurements. RS 232 is standard. Soft keys give the user access to digital calibration, linearization and features like user programmable force filter, programmable length offset, user customized print headings, automatic calculation of mean, standard deviation and range of data. Use the RS 232 port for statistical printout or talking to a PC. It works great with LSI’s SSS, a PC-based “Statistical & Spreadsheet Interface Software,” which features dynamic data exchange, allowing you to communicate to spreadsheets like Excel. Measure torque in in-lb, N-mm, gm-mm, kg-m, in-oz, ft-lb, N-m, kg-mm and kg-cm.

Torsion Tests Under Compression

Create a more life-like test with optional adjustable compression. The X-Axis Compression Adjuster allows you to apply up to 250 lb of compression force, (based on prior force / length measurements) and gain more accurate readings for your part tests.

Create a more life-like test with optional adjustable compression. The X-Axis Compression Adjuster allows you to apply up to 250 lb of compression force, (based on prior force / length measurements) and gain more accurate readings for your part tests.

Use the optional X-Axis Linear Scale to set compression by length.

.embed-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%; }

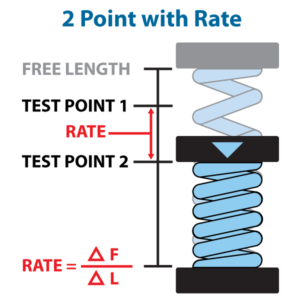

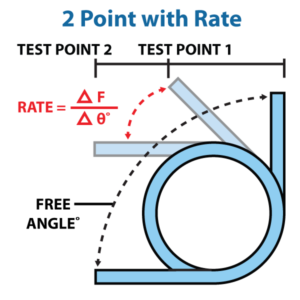

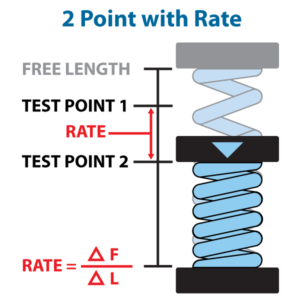

2 Point with Rate

Test two points with spring rate calculation in one deflection of the spring.

2 Point With Rate is a tester software option that allows you to calculate the rate (or spring constant) between two points. To use this feature, press the Test Mode button to enter 2 Point With Rate mode. Set your first test point by using the tester’s force and length readings as a guide and pressing the F1 button. Set the second test point using the same method. When both test points are set the tester automatically calculates and displays the rate as shown. This is all accomplished in just one deflection of the spring!

2 Point with Rate is a tester software feature. A PC is not needed for this software.

Click for Print Samples

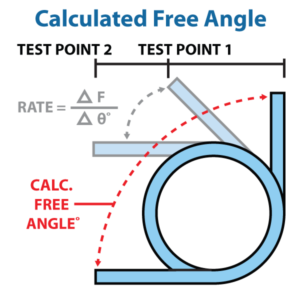

Calculated Free Angle

Two-point testing with automatic free angle calculation. Calculate your torsion springs free angle without measuring by testing two points in one deflection of the spring.

[/col][/row]

Three Rotational Stops

For repetitive applications requiring multiple test points on a given spring, the Torsion Spring Tester comes equipped with three stops that can be preset to any given test point.

Battery or AC Powered

A self-contained tester with an internal, rechargeable battery pack (approximately 8-10 hours of continuous operation). AC charger also included with each tester.

Loading Capability

The TST comes standard with two cranking ratios, giving the operator flexibility when testing. Use the 1:1 ratio for light springs or course movements. Choose the 40:1 micro adjust to fine tune the measurements.

The TST is a manually operated torque / angle tester that is available in seven force ranges: 0.3, 3, 25, 100, 200, 500 and 1,300 in-lb. The solid steel base and aluminum frame is rugged for durability in many different testing environments. The TST, like all LSI testers, comes standard with an NIST traceable certificate of calibration.

The TST is a manually operated torque / angle tester that is available in seven force ranges: 0.3, 3, 25, 100, 200, 500 and 1,300 in-lb. The solid steel base and aluminum frame is rugged for durability in many different testing environments. The TST, like all LSI testers, comes standard with an NIST traceable certificate of calibration. Using LSI’s custom interchangeable tooling technique, you can machine tooling blanks to fit your specific applications or send the information to us and we will do the work for you.

Using LSI’s custom interchangeable tooling technique, you can machine tooling blanks to fit your specific applications or send the information to us and we will do the work for you. With the universal tooling supplied by LSI, you can test many parts with no special fittings. This is great for unique or one-time job runs with a minimum of setup time.

With the universal tooling supplied by LSI, you can test many parts with no special fittings. This is great for unique or one-time job runs with a minimum of setup time. Switch from one torque cartridge to another in just minutes, allowing for a single tester to test a wide range of capacities quickly and accurately. Smart torque cartridges can be digitally calibrated. You can also send in only the smart torque cartridge to LSI for remote calibration (full system calibration is better than individual component calibration).

Switch from one torque cartridge to another in just minutes, allowing for a single tester to test a wide range of capacities quickly and accurately. Smart torque cartridges can be digitally calibrated. You can also send in only the smart torque cartridge to LSI for remote calibration (full system calibration is better than individual component calibration). This software option lets the user program the limit lights to make sorting reliable and efficient. This option also uses the programmed limits to enable the Mean, Standard Deviation, Range, Range Chart, Histogram, Cp and Cpk statistical printed outputs. Limit Lights and Full Statistics Analysis is a tester software feature. A PC is not needed for this software.

This software option lets the user program the limit lights to make sorting reliable and efficient. This option also uses the programmed limits to enable the Mean, Standard Deviation, Range, Range Chart, Histogram, Cp and Cpk statistical printed outputs. Limit Lights and Full Statistics Analysis is a tester software feature. A PC is not needed for this software. Create a more life-like test with optional adjustable compression. The X-Axis Compression Adjuster allows you to apply up to 250 lb of compression force, (based on prior force / length measurements) and gain more accurate readings for your part tests.

Create a more life-like test with optional adjustable compression. The X-Axis Compression Adjuster allows you to apply up to 250 lb of compression force, (based on prior force / length measurements) and gain more accurate readings for your part tests.