LSI’s STAR Series testers are motorized compression and extension force and length testing systems.

- Standard 15″ range (11″ + 4″ load cell offset)

- 2,000 or 3,000 lbf High Capacity Drive (240 VAC, single phase)

- Easy access to emergency shutoff

LSI’s STAR Series testers are motorized compression and extension force and length testing systems.

LSI’s STAR Series testers are motorized compression and extension force and length testing systems. With their numerous load range capacities and load cell interchangeability, these systems will test a wide variety of springs or other test material.

LSI’s STAR Series testers are motorized compression and extension force and length testing systems. With their numerous load range capacities and load cell interchangeability, these systems will test a wide variety of springs or other test material.

The RoboSTAR can accommodate a high performance 2,000 or 3,000 lb drive with super precision capabilities.

This tester has solid machined aluminum construction with a heavy steel support riser as a backbone to build on, making it the most rigid workbench machine built by LSI. This C-frame style has high rigidity and low deflection characteristics that are commonly found in bridge style frames. Linear guideways make for smooth and precise motion and a servo motor and ball screw drive offers reliable and responsive testing. Unseen features like load cell and frame deflection compensation, length linearization, and smart load cell recognition make accurate and consistent testing easy by any operator.

These testers have software and mechanical overloads that protect from load cell stress damage – use our testers with confidence. Switching load cells is fast – it takes just minutes to change each load cell. Each smart interchangeable load cell has a signature that is read by the tester on power up and requires no special steps by the user. Change it and forget it!

Use LSI accessories to easily test difficult parts. A wide variety of load buttons, support platforms and hooks make the tester very versatile and convenient to use. The STAR series comes standard with 5/16-18 tapped holes in the center of the platforms for accessories or special fixtures.

These testers have a fast learn cycle. A new operator can make or modify test programs within minutes. Full use of all of the features can be learned in only an hour or two. The STAR system will be in use the same day it arrives and will be indispensable within a short time.

Each machine comes standard with NIST traceable calibration and is very insensitive to temperature variations for accurate testing over a wide range of conditions. In less than five minutes, accuracy can be verified by the user to comply with ISO 9000 standards, with built in shunt calibration or by using our Master Calibrated Spring.

Flexibility is the key to the STAR Series testing systems. These stand-alone systems are excellent for use in an inspection room or test lab yet are rugged enough for use right on the factory floor. They have incredible flexibility, allowing the operator to test a huge variety of test points and test configurations; from a simple one point F@L test to more complex 99 point tests, the STAR will get the job done.

Two load cell mounting spots increase the maximum range by 4″

Two load cell mounting spots increase the maximum range by 4″Automated Operation

Computer controlled, motorized compression/extension for the same test every time.

Operator Independent Repeatable Testing

Your setup person, operator and inspector all get the same answers every time with simple programming, standardized setup, automatic testing and no button printing. The STAR is capable of good gage R&R’s on tight tolerance springs.

Inspection

The STAR is an excellent tool for the inspection lab. The user can perform many tests, from springs to tensile testing and other various materials testing.

Productivity

Typical test cycles range from 3.5 to 10 seconds. Send samples and test requirements to LSI for a specific rate quotation. Production monitor screens to setup and measure testing productivity.

Test Flexibility

Test one or two points, preset, measure free length, initial tension, rate or multiple rate and compare to specifications all in a single test cycle.

Versatility

Having interchangeable load cells means that the same tester can be used to test from 0.5 g to 3,000 lbf. Stretch your spring extension testing capability with the modular extension bridge assembly.

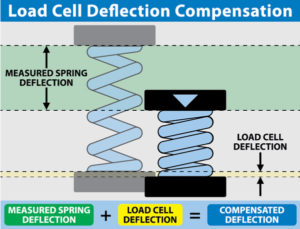

What is length deflection compensation?

What is length deflection compensation?

All force/length testing devices, regardless of manufacturer, have additional deflection by the load cell and tester frame which occurs as the spring is loaded. If you buy/use a tester without deflection compensation, measurements might include significant length errors.

Spring deflection, also known as spring travel or motion, is the action of a compression spring compressing (being pushed), an extension spring extending (being pulled), or a torsion spring winding (being twisted) when a load is applied or released. This is one characteristic (spring deflection) that is measured by a Larson Systems Spring Tester.

Larson Systems has BUILT-IN Length Deflection Compensation so that the user does not have to calculate and apply length corrections. Most competitors do not have length deflection compensation.

With a Larson Systems product, forget about calculating load cell and frame deflection when testing, we’ve got you covered.

| Load Cell Capacity |

Standard Resolution | |

| 0-20% FS | 20-100% FS | |

| 2 lbf | 0.0001 lbf | 0.001 lbf |

| 907 g | 0.02 g | 0.2 g |

| 8.9 N | 0.0002 N | 0.002 N |

| 11 lbf | 0.0002 lbf | 0.002 lbf |

| 5 kg | 0.1 g | 1 g |

| 49 N | 0.001 N | 0.01 N |

| 22 lbf | 0.0005 lbf | 0.005 lbf |

| 10 kg | 0.2 g | 2 g |

| 98 N | 0.002 N | 0.02 N |

| 66 lbf | 0.001 lbf | 0.01 lbf |

| 30 kg | 0.5 g | 5 g |

| 294 N | 0.005 N | 0.05 N |

| 110 lbf | 0.002 lbf | 0.02 lbf |

| 50 kg | 0.001 kg | 0.01 kg |

| 489 N | 0.01 N | 0.1 N |

| 200 lbf | 0.005 lbf | 0.05 lbf |

| 91 kg | 0.002 kg | 0.02 kg |

| 890 N | 0.02 N | 0.2 N |

| 550 lbf | 0.01 lbf | 0.1 lbf |

| 249 kg | 0.005 kg | 0.05 kg |

| 2,447 N | 0.05 N | 0.5 N |

| 1,000 lbf | 0.02 lbf | 0.2 lbf |

| 454 kg | 0.01 kg | 0.1 kg |

| 4,448 N | 0.1 N | 1 N |

| 2,000 lbf | 0.05 lbf | 0.5 lbf |

| 907 kg | 0.02 kg | 0.2 kg |

| 8,896 N | 0.2 N | 2 N |

| 3,000 lbf | 0.1 lbf | 1 lbf |

| 1,361 kg | 0.05 kg | 0.5 kg |

| 13,345 N | 0.5 N | 5 N |

| Accuracy = ± Full Scale Resolution x 2 | ||

| Description | Part Number | |

|---|---|---|

| RoboSTAR 11" Stroke, Sm Base 5' Cables | 050-0000-0094-00 | Get a Quote |

| RoboSTAR 11" Stroke, Lg Base 5' Cables | 050-0000-0094-01 | Get a Quote |

| RoboSTAR 11" Stroke, Sm Base 15' Cables | 050-0000-0094-02 | Get a Quote |

| RoboSTAR 11" Stroke, Lg Base 15' Cables | 050-0000-0094-03 | Get a Quote |

| RoboSTAR Flash Control Base Unit 24" Stroke | 050-0000-0095-00 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| 2,000 lbf High Capacity Drive (240 VAC, single phase) | 025-0000-0419-00 | Get a Quote |

| 3,000 lbf High Capacity Drive (240 VAC, single phase) | 025-0000-0419-02 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Sorter / Automation Interface Port | 025-0000-0299-01 | Get a Quote |

| Star PinThru Platform, Ø 1.000, Platform 8.00 OD | 018-0000-3014-10 | Get a Quote |

| Lower Platform, 5/8-18 Threaded Center hole | 018-0000-1874-01 | Get a Quote |

| FLASH, Automation Interface | 025-1000-0619-00 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| High Resolution Length | 025-0000-0417-00 | Get a Quote |

| High Resolution Length (0.0001 in) | 025-0000-0418-00 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Basic Software Package | 050-1000-0039-00 | Get a Quote |

| Extra Software Package | 050-1000-0039-01 | Get a Quote |

| Pro Spring Software Package | 050-1000-0039-02 | Get a Quote |

| Fatigue Testing Software Package | 050-1000-0039-03 | Get a Quote |

| Pro Material Software Package | 050-1000-0039-04 | Get a Quote |

| Pro Ultimate Software Package | 050-1000-0039-05 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| STAR Thru Rod Smart Load Cell - 22 lbf (2" thru hole) | 025-0000-0414-12 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 44 lbf (2" thru hole) | 025-0000-0414-13 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 132 lbf (2" thru hole) | 025-0000-0414-14 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 220 lbf (2" thru hole) | 025-0000-0414-15 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 400 lbf (2" thru hole) | 025-0000-0414-16 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 1,000 lbf (2" thru hole) | 025-0000-0414-17 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 2,000 lbf (2" thru hole) | 025-0000-0414-18 | Get a Quote |

| STAR Thru Rod Smart Load Cell - 2,000 lbf (2" thru hole) | 025-0000-0414-19 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| 2 lbf Smart Interchangeable Load Cell (2" Ø platform) | 025-0000-0414-01 | Get a Quote |

| 11 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0414-02 | Get a Quote |

| 22 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0414-03 | Get a Quote |

| 66 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0414-04 | Get a Quote |

| 110 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0414-05 | Get a Quote |

| 200 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0414-06 | Get a Quote |

| 550 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0415-01 | Get a Quote |

| 1,000 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0415-02 | Get a Quote |

| 2,000 lbf Smart Interchangeable Load Cell (3.5" Ø platform) | 025-0000-0415-03 | Get a Quote |

| 2,000 lbf Smart Interchangeable Load Cell (3.5" Ø platform, for high rate parts) | 025-0000-0416-01 | Get a Quote |

| 3,000 lbf Smart Interchangeable Load Cell (3.5" Ø platform, 2" Ø thru-hole) | 025-0000-0414-19 | Get a Quote |

| Description | Part Number | |||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Fatigue Plate Assembly (Requires Fatigue Test Function)Fatigue Plate AssemblyPart Number: 025-0000-0449-01 Test the endurance of your part, and keep track of it’s performance throughout the test. With capability of up to 10 million test cycles, you can put your part in and forget about it! And if the part falls below spec, the test automatically stops. Test up to 8 springs or other parts at a time with Larson’s Fatigue Plate Assembly. Special knobs keep parts in place during testing; choose diameters between 3/4″, 1/2″, and 1/4″.

| 025-0000-0449-00 | Get a Quote | ||||||||||||||||||||||||||||||||||||||||

Dust CoverDust CoverPart Number: 059-1000-0023-00 | 059-1000-0023-00 | Get a Quote | ||||||||||||||||||||||||||||||||||||||||

8" Ø Platforms (5/16-18 thread)Platforms – 8″ ØPart Number: 025-0000-0439-01 For testing larger diameter compression parts. | 025-0000-0439-01 | Get a Quote | ||||||||||||||||||||||||||||||||||||||||

| Description | Part Number | |

|---|---|---|

| Inkjet Printer (with install driver) | 025-0000-0464-01 | Get a Quote |

| Laser Printer (with install driver) B & W | 025-0000-0464-03 | Get a Quote |

| Laser Pro Printer (with install driver) B & W | 025-0000-0464-04 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| On-Site Installation & Training | 100-0000-0006-00 | Get a Quote |