One of our largest spring testers, the FLASH 36’s framework is capable of testing parts with loads up to 50,000 lbf.

- Standard 36″ stroke

- 240 volt three phase servo drive

- Easy access to emergency shutoff

One of our largest spring testers, the FLASH 36’s framework is capable of testing parts with loads up to 50,000 lbf.

One of our largest spring testers, the FLASH 36’s framework is capable of testing parts with loads up to 50,000 lbf. This tester is designed around large parts and heavy loads with plate diameters up to 18″ and parts up to 36″ in length. The FLASH 36 has a completely interlocked enclosure and a removable top plate to accommodate an optional pneumatic thru-rod assembly (up to 6″ Ø) for testing parts that tend to buckle under load.

One of our largest spring testers, the FLASH 36’s framework is capable of testing parts with loads up to 50,000 lbf. This tester is designed around large parts and heavy loads with plate diameters up to 18″ and parts up to 36″ in length. The FLASH 36 has a completely interlocked enclosure and a removable top plate to accommodate an optional pneumatic thru-rod assembly (up to 6″ Ø) for testing parts that tend to buckle under load.

In August, 2012, we completed a redesign and build of the FLASH 36 for a large transit authority that included a Spring Auto-Loader mechanism for shuttling heavy parts (like 100 lb railcar suspension springs) in and out of the tester. We also modified the loading door and thru-rod assembly to be pneumatically powered. In addition to these upgrades, we added an optional spring squareness tester attachment that fits onto the machine next to the Spring Auto-Loader so the operator can manually test each spring’s straightness.

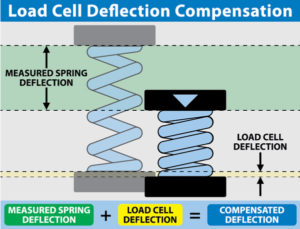

What is length deflection compensation?

What is length deflection compensation?

All force/lengh testing devices, regardless of manufacturer, have additional deflection by the load cell and tester frame which occurs as the spring is loaded. If you buy/use a tester without deflection compensation, measurements might include significant length errors.Spring deflection, also known as spring travel or motion, is the action of a compression spring compressing (being pushed), an extension spring extending (being pulled), or a torsion spring winding (being twisted) when a load is applied or released. This is one characteristic (spring deflection) that is measured by a Larson Systems Spring Tester.

Larson Systems has BUILT-IN Length Deflection Compensation so that the user does not have to calculate and apply length corrections. Most competitors do not have length deflection compensation.

With a Larson Systems product, forget about calculating load cell and frame deflection when testing, we’ve got you covered.

| Load Cell Capacity |

Standard Resolution | |

| 0-20% FS | 20-100% FS | |

| 1,000 lbf | 0.02 lbf | 0.2 lbf |

| 454 kg | 0.01 kg | 0.1 kg |

| 4,448 N | 0.1 N | 1 N |

| 3,000 lbf | 0.1 lbf | 1 lbf |

| 1,361 kg | 0.05 kg | 0.5 kg |

| 13,345 N | 0.5 N | 5 N |

| 6,000 lbf | 0.2 lbf | 2 lbf |

| 2,722 kg | 0.1 kg | 1 kg |

| 26,690 N | 1 N | 10 N |

| 10,000 lbf | 0.2 lbf | 2 lbf |

| 4,536 kg | 0.1 kg | 1 kg |

| 44,482 N | 1 N | 10 N |

| 20,000 lbf | 0.5 lbf | 5 lbf |

| 9,072 kg | 0.2 kg | 2 kg |

| 88,964 N | 2 N | 20 N |

| 35,000 lbf | 1 lbf | 10 lbf |

| 15,875 kg | 0.5 kg | 5 kg |

| 155,690 N | 5 N | 50 N |

| 50,000 lbf | 2 lbf | 20 lbf |

| 22,679 kg | 1 kg | 10 kg |

| 222,411 N | 10 N | 100 N |

| Accuracy = ± Full Scale Resolution x 2 | ||

| Description | Part Number | |

|---|---|---|

| FLASH 36 (35,000 lb capacity, 18" Ø platforms) w/Auto Loader | 050-0000-0752-01 | Get a Quote |

| FLASH 36 (35,000 lb capacity, 18" Ø platforms) | 050-0000-0141-00 | Get a Quote |

| FLASH 36 (35,000 lb capacity, 18" Ø platforms) Thru Rod | 050-0000-0141-01 | Get a Quote |

| FLASH 36 (50,000 lb capacity, 18" Ø platforms) | 050-0000-0100-00 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Spring Auto-Loader | 025-0000-0882-01 | Get a Quote |

| Sorter / Automation Interface Port | 025-0000-0299-00 | Get a Quote |

ASTM Squareness TesterSpring Squareness TesterPart Number: 025-0000-0894-00 Convenient Mounting Location The Spring Squareness Tester has indicating marks that allow you to measure spring straightness up to 5 degrees in one direction and 10 degrees in the opposite direction. | 025-0000-0894-00 | Get a Quote |

| High Resolution Length (0.0001) in. resolution) | 025-0000-0757-00 | Get a Quote |

| Telescoping Metal Ball Screw Covers | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Basic Software Package | 050-1000-0039-00 | Get a Quote |

| Extra Software Package | 050-1000-0039-01 | Get a Quote |

| Pro Spring Software Package | 050-1000-0039-02 | Get a Quote |

| Fatigue Testing Software Package | 050-1000-0039-03 | Get a Quote |

| Pro Material Software Package | 050-1000-0039-04 | Get a Quote |

| Pro Ultimate Software Package | 050-1000-0039-05 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| 1,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-01 | Get a Quote |

| 3,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-03 | Get a Quote |

| 6,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-06 | Get a Quote |

| 10,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-10 | Get a Quote |

| 20,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-20 | Get a Quote |

| 35,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-35 | Get a Quote |

| 50,000 lbf Load Cell for Auto-Loader with TUL (18" Ø platform) | 025-0000-0885-50 | Get a Quote |

| 500 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-03 | Get a Quote |

| 1,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-02 | Get a Quote |

| 2,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-01 | Get a Quote |

| 3,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-00 | Get a Quote |

| 6,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-06 | Get a Quote |

| 10,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-07 | Get a Quote |

| 15,000 lbf Interchangeable Load Cell with TUL (12" Ø platform) | 025-0000-0262-09 | Get a Quote |

| 500 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-16 | Get a Quote |

| 1,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-14 | Get a Quote |

| 2,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-15 | Get a Quote |

| 3,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-10 | Get a Quote |

| 6,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-11 | Get a Quote |

| 10,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-12 | Get a Quote |

| 15,000 lbf Interchangeable Load Cell (12" Ø platform) | 025-0000-0262-17 | Get a Quote |

| 20,000 lbf Load Cell (18" Ø platform, integrated TUL) | 025-0000-0254-20 | Get a Quote |

| 35,000 lbf Load Cell (18" Ø platform, integrated TUL) | 025-0000-0254-30 | Get a Quote |

| 50,000 lbf Load Cell (18" Ø platform, integrated TUL) | 025-0000-0254-50 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Thru Rod Assembly (screw driven) | 025-0000-0265-16 | Get a Quote |

| Thru Rod Tool Rack | 025-0000-1282-00 | Get a Quote |

| 1" - 6.5 OD Adjustable Thru-Rod Assembly | Get a Quote | |

| 3" - 6.5 OD Adjustable Thru-Rod Assembly | 025-0000-0259-00 | Get a Quote |

Extension Spring Clevis for 20,000 lbf Load CellExtension Spring ClevisPart Number: 025-0000-0258-00 Extension spring clevis for the 20,000 lb load cell. | 025-0000-0258-00 | Get a Quote |

Extension Spring Clevis for 35,000 lbf Load CellExtension Spring ClevisPart Number: 025-0000-0258-01 Extension spring clevis for the 35,000 lb load cell. | 025-0000-0258-01 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| Inkjet Printer (with driver install) | 025-0000-0464-01 | Get a Quote |

| Laser Printer (with driver install) B & W | 025-0000-0464-03 | Get a Quote |

| Laser Pro Printer (with driver install) B & W | 025-0000-0464-04 | Get a Quote |

| Description | Part Number | |

|---|---|---|

| On-Site Installation & Training | 100-0000-0006-01 | Get a Quote |