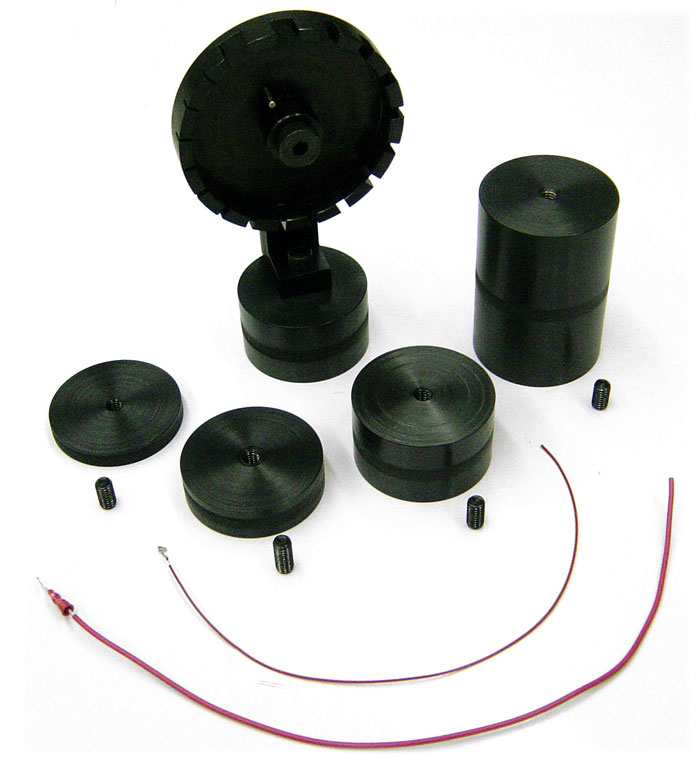

Wire Crimp Test Gauge

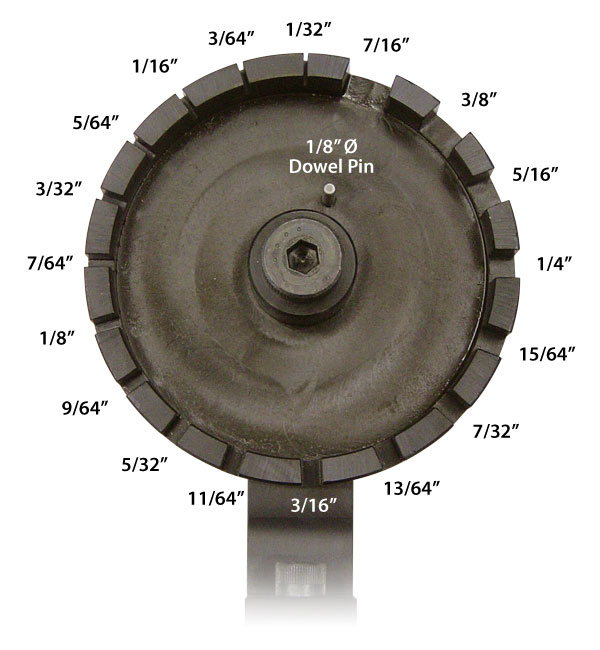

The simplest and most straight-forward pull test for wire crimps is LSI’s Wire Crimp Test Gauge. This crimp wheel fixture features 18 slots ranging from 0.031″ to 0.437″ and can accommodate up to #4 gage wire. Immediately test your wire crimp’s integrity by inserting the crimped end of the wire into the appropriate slot of the wheel pull fixture, and lift up until either the crimp slips free (bad) or the weight is lifted free (good). A small dowel pin in the large slot is available for testing ring-type wire terminals.

The upper crimp fixture itself weighs 1.5 lb, and comes with the following detachable weights: 0.5 lb, 1 lb, 2 lb, 2 lb, and 5 lb. The maximum configurable weight is 12 lb.