SDHT 2000 – Super Digital Hand Tester

This is the heavy-duty version of our SDHT. Our most accurate manual tester, the SDHT 2000 has Quick Change load cells that allow you to measure grams to two decimal places, change the load cell and test up to 2,000 pounds. Its rugged two post design minimizes frame deflection and gives you the most versatility and productivity in a single tester. The tester has a two-line backlit LED display of force and length and has deflection compensation for accurate readings at all times.

This is the heavy-duty version of our SDHT. Our most accurate manual tester, the SDHT 2000 has Quick Change load cells that allow you to measure grams to two decimal places, change the load cell and test up to 2,000 pounds. Its rugged two post design minimizes frame deflection and gives you the most versatility and productivity in a single tester. The tester has a two-line backlit LED display of force and length and has deflection compensation for accurate readings at all times.

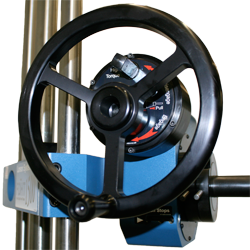

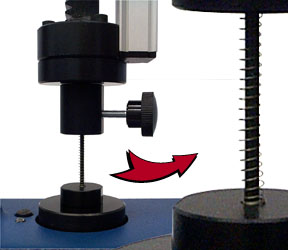

The SDHT 2000 is made from a combination of billet aluminum and precision ground steel parts. The rack and pinion lever drive can be upgraded to our Micro Length Adjust assembly for fine length adjustments. The SDHT 2000 is also equipped with two positive stops to be used for repetitive testing and comes standard with a 0.437” Ø thru-hole for centering shafts for supporting buckling type compression springs. A stroke lock helps keep things in place while you take measurements or configure tooling. The tester has 5/8-18 tooling holes for convenient fitting.

SDHT software includes these powerful features, making testing easy and productive:

- Limit Lights

Part sorting and a statistical summary printout that includes a histogram and data run chart.

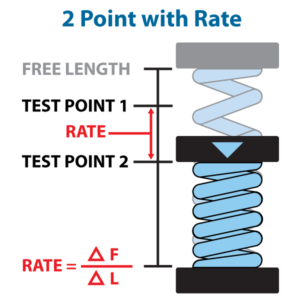

- Two-Point with Rate

Test two points with spring rate calculation in one deflection of the spring.

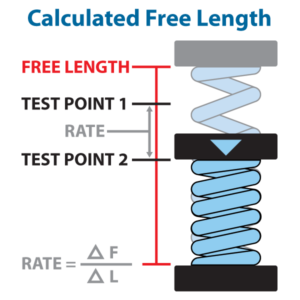

- Calculated Free Length Measurement

Calculate the free length of a compression spring.

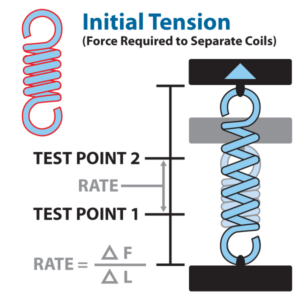

- Initial Tension Measurement

Calculate the initial tension of an extension spring.

Specifications

- Compression and extension testing of force and length

- Built-in 0.437″ thru-hole

- Internal 8 hour battery for portable use

- RS 232 data communications port

- User programmable filter

- Length / force offset

- Customizable print headings

- Statistical summary printout

- Built-in 1,800 test point data logger

- Complete computerized tester diagnostics

- 20-bit internal force resolution

- Load cell and frame deflection compensation

- Mechanical and software overload protection

- Built-in shunt calibration verification

- Digital calibration and linearization

- Backlit digital LED display of force and length

- Wipe-clean embossed key faceplate

- Push-button force and length zeroing

- NIST traceable calibration

- Tracking or peak modes (2,000 samples / sec)

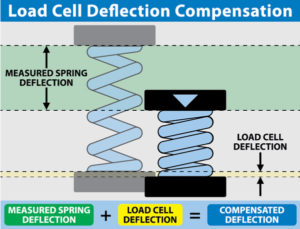

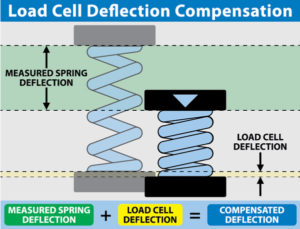

Includes Length Deflection Compensation

What is length deflection compensation?

What is length deflection compensation?

All force/lengh testing devices, regardless of manufacturer, have additional deflection by the load cell and tester frame which occurs as the spring is loaded. If you buy/use a tester without deflection compensation, measurements might include significant length errors.

Spring deflection, also known as spring travel or motion, is the action of a compression spring compressing (being pushed), an extension spring extending (being pulled), or a torsion spring winding (being twisted) when a load is applied or released. This is one characteristic (spring deflection) that is measured by a Larson Systems Spring Tester.

Larson Systems has BUILT-IN Length Deflection Compensation so that the user does not have to calculate and apply length corrections. Most competitors do not have length deflection compensation.

With a Larson Systems product, forget about calculating load cell and frame deflection when testing, we’ve got you covered.

SDC Software Demo

Try our software for “Spring Testing Data at Your Fingertips”. With Larson System’s SDC Software, your spring testing data can be accessed, stored and manipulated as it is generated. Store specifications for different parts, load a set of parameters and clearly see which springs are out of spec using the on-screen graphical representation of the testing results. Save and print results or open the results file in Microsoft Excel. You have complete control of your testing data.

Free Demo

What is length deflection compensation?

What is length deflection compensation?